Learn how to repair rust on furnace, spot hidden warning signs, and prevent corrosion from turning into costly breakdowns or safety risks.

Corrosion can quickly ruin your heating system’s safety, efficiency, and overall lifespan. What starts as a small orange spot today can lead to a dangerous breakdown tomorrow. Learning how to repair rust on a furnace is the best way to save your equipment and your wallet. In this guide, we’ll show you how to spot the warning signs and explain the best steps for furnace repair to keep your home warm and safe.

What Causes Rust on a Furnace?

Rust on a furnace is rarely just a surface issue. Most often, it signals underlying problems related to moisture, airflow, or installation. Common causes include the following:

- Excess moisture or condensation inside the furnace cabinet

Warm air inside the furnace can meet cooler metal surfaces, creating condensation. Over time, this moisture can accumulate and cause corrosion on panels, burners, or other internal parts. High indoor humidity, especially in basements or poorly ventilated areas, can make this problem worse, allowing rust to form faster.

- Poor ventilation or exhaust leaks

Furnaces rely on proper ventilation to safely expel combustion gases. If vents are blocked, damaged, or improperly installed, moisture-laden exhaust can linger inside the system. This trapped moisture accelerates rust formation and may compromise the efficiency and safety of the furnace. Poor ventilation can also pose serious health risks, as lingering combustion gases such as carbon monoxide may accumulate indoors and cause headaches, dizziness, respiratory issues, or even life-threatening poisoning.

- Clogged or improperly installed drainage systems

Many modern furnaces generate condensation that must drain away through a condensate line. If this line becomes clogged, damaged, or installed incorrectly, water can pool inside the furnace cabinet. Standing water can quickly corrode metal components, leading to structural damage and reduced lifespan.

- Installation flaws that expose metal components to humidity

Incorrect installation, such as poor sealing, improper positioning near humid areas, or failure to insulate critical parts, can expose metal surfaces to constant moisture. Even small gaps or misaligned panels can allow humid air to contact internal components, accelerating rust over time.

- Cracked or damaged internal parts

Over time, furnace components like heat exchangers or drain pans may develop cracks or wear. These small openings can trap water or condensation in places that are hard to see, leading to hidden rust that often goes unnoticed until it affects performance or safety.

When condensation, airflow, or drainage issues are present, rust may indicate deeper safety risks, including restricted airflow, compromised combustion, or even carbon monoxide poisoning. Addressing the underlying cause is critical before attempting to repair rust on a furnace, ensuring the problem doesn’t return or worsen.

How to Identify Rust Damage on Your Furnace

Rust damage doesn’t always appear overnight. It often develops gradually, starting on the surface and progressing into critical internal components if left unchecked. Knowing how to spot the early warning signs can help you address issues before they compromise your furnace’s safety, efficiency, or lifespan.

Common Visual Signs of Rust

A basic visual inspection can reveal early corrosion. Watch closely for:

- Reddish-brown discoloration on exterior panels

- Bubbling, peeling, or flaking paint

- Corrosion around seams, screws, or access doors

- Rust forming near vents or exhaust connections

While these signs may begin as surface damage, they can also indicate deeper internal corrosion that requires professional attention.

Performance Issues Linked to Rust

Rust can silently affect your furnace’s performance long before you notice visible damage. Common symptoms to watch for include:

- Reduced heating efficiency or uneven temperature

Rust on internal components can interfere with heat transfer, causing some rooms to feel cooler while others overheat. Your furnace may also run longer than usual to maintain the desired temperature, driving up energy costs.

- Metallic odors or unusual rattling or banging sounds

Corrosion can cause metal parts to warp or loosen, creating strange noises or metallic smells during operation. These sounds often indicate that rust has affected critical components, like burners, heat exchangers, or vents.

- Weak or inconsistent airflow throughout the home

Rust buildup can restrict airflow by partially blocking ducts or damaging fans. Reduced airflow not only affects comfort but can also strain the furnace, leading to more serious mechanical issues over time.

When these performance problems appear alongside visible rust, it’s a strong signal that your furnace may require professional evaluation. At this point, it’s important to consider whether repairing the rusted furnace is safe and effective, or if replacement is the more reliable and long-term solution.

Is Rust on a Furnace Dangerous?

The level of danger depends on where the rust is located and how deeply it has penetrated the system. Understanding the difference can help you decide when monitoring is enough and when immediate action is necessary. The key distinction is between surface rust and structural rust.

- Surface rust typically affects exterior panels and is largely cosmetic.

- Structural rust compromises internal components and load-bearing parts.

Rust on the heat exchanger is especially dangerous. In situations like these, DIY repairs are unsafe, and a professional inspection is essential to protect your home and health.

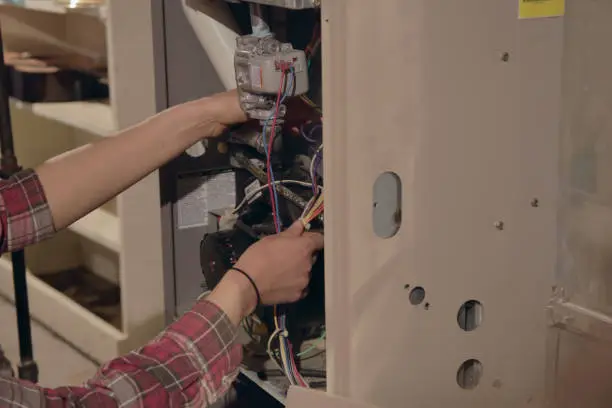

How to Repair Rust on a Furnace (DIY vs Professional)

Repairing rust on a furnace depends on the severity and location of the corrosion. While minor surface rust can sometimes be addressed with basic DIY methods, deeper or internal rust often requires professional expertise. Knowing where to draw the line is essential for maintaining both system performance and household safety.

Minor Rust Repairs You Can Handle

DIY solutions are only suitable for cosmetic rust that does not impact your furnace’s performance or safety. If the corrosion is limited to exterior panels, you can follow these steps to slow its progression.

- Turn off power and gas to the furnace.

Safety first! Always shut off electricity and gas before touching any part of your furnace.

- Lightly sand or wire-brush rusted areas.

Remove surface rust and any loose paint using fine sandpaper or a wire brush. This helps prepare the metal for protection.

- Clean all debris and residue thoroughly.

Wipe down the area to remove dust, rust particles, and grease. A clean surface ensures that protective coatings adhere properly.

- Apply a rust inhibitor designed for HVAC equipment.

Use a rust-preventative spray or coating specifically made for furnaces. This helps slow further corrosion and protects the metal temporarily.

- Finish with high-heat furnace paint.

Coat the repaired area with high-temperature paint to seal it from moisture and improve appearance.

These steps provide temporary protection, not a permanent fix. Cosmetic repairs can delay rust, but they won’t address underlying moisture or airflow issues. If rust is more than surface-level or affects internal components, a professional inspection is essential.

When to Call a Professional for a Rusted Furnace

Call a professional immediately if you notice the following:

- Rust on the heat exchanger

This is the most serious issue. A rusted or cracked heat exchanger can leak carbon monoxide. Do not run the furnace. Call a professional right away.

- Flaking, deep, or spreading rust

Surface discoloration is one thing. Thick, flaky, or expanding rust suggests structural damage. This can lead to air leaks, poor combustion, or failure.

- Carbon monoxide detector alerts

Even without visible rust damage, this is a critical warning. Leave the house and call emergency services or an HVAC professional.

- Water pooling or active leaks

Rust caused by ongoing moisture from a humidifier, condensate line, or exhaust vent will worsen quickly. A technician needs to find and fix the moisture source.

Call a professional soon (non-emergency) if you notice the following:

- Rust on the burner assembly

This can affect flame quality and efficiency and may cause delayed ignition or uneven heating.

- Declining performance

Uneven heating, longer run times, or rising energy bills combined with rust are red flags.

- Furnace is 15+ years old

Rust often signals the furnace is nearing the end of its lifespan. A professional can assess whether repair or replacement makes more sense.

Can Rust Be Prevented in the Future?

Yes! Rust can often be prevented with proactive care and consistent maintenance. Since moisture is the primary cause of furnace corrosion, reducing exposure and addressing small issues early can significantly extend the life of your heating system. Preventative best practices include:

- Scheduling annual professional furnace inspections

- Routinely cleaning vents, condensate drains, and drainage lines

- Controlling indoor humidity levels, especially in basements or utility rooms

- Applying protective or anti-corrosion coatings during maintenance visits

Following regular HVAC maintenance practices helps identify moisture problems before they lead to rust, improving system efficiency and protecting your furnace from long-term damage.

Repair vs Replacement – Making the Right Decision

Choosing between repairing or replacing a rusted furnace isn’t always straightforward. The right decision depends on the condition of your system, long-term costs, and how well the furnace can continue to operate safely and efficiently. When evaluating your options, consider the following:

- The age of the unit – Systems over 15 years old often favor replacement.

- The severity and location of the rust damage, especially on critical components

- Repair costs compared to potential gains in energy efficiency and reliability

In many cases, investing in a newer system offers improved safety, better comfort, and long-term savings, making replacement the smarter choice over repeated repairs.

Final Thoughts on Rust Damage and Furnace Safety

Rust should never be ignored. While light surface corrosion can sometimes be managed, structural rust requires professional attention. Knowing how to repair rust on furnace and when replacement is the safer option helps protect your home and your family. Keep your furnace winter-ready by spotting rust early, performing routine maintenance, and addressing corrosion before it affects safety or efficiency.

Don’t leave your family’s safety to chance. Contact On Point Service Company today for a professional furnace evaluation and catch rust damage before it turns into a costly emergency.